In the world of precision engineering, construction, and manufacturing, the right tools can make all the difference. Whether you’re a professional welder, a hobbyist, or someone working on intricate DIY projects, understanding the applications and benefits of tools like an air hot gun, a laser welding machine, and various welding equipment is crucial. Let’s explore how these tools can enhance your work, improve accuracy, and expand your capabilities.

Air Hot Gun: Versatility and Precision in Heating

An air hot gun is a versatile tool that’s widely used in various applications, from electronics repair to construction. Here’s why it’s a must-have:

Precision Heating: An air hot gun allows you to apply controlled heat to specific areas, making it ideal for tasks such as removing paint, drying materials, and even soldering electronic components. Its ability to focus heat precisely where it’s needed ensures that you can complete delicate tasks without damaging surrounding areas.

Versatility: The applications of an air hot gun are vast. It’s used in automotive repairs for shrinking tubing, loosening bolts, and even defrosting frozen parts. In electronics, it’s essential for tasks like desoldering and heat-shrinking components. It’s also a valuable tool in construction for tasks such as softening adhesives and bending plastics.

Adjustable Settings: High-quality air hot guns come with adjustable temperature and airflow settings, giving you control over the intensity of the heat. This makes it easier to handle various materials and tasks, whether you need gentle warmth or intense heat.

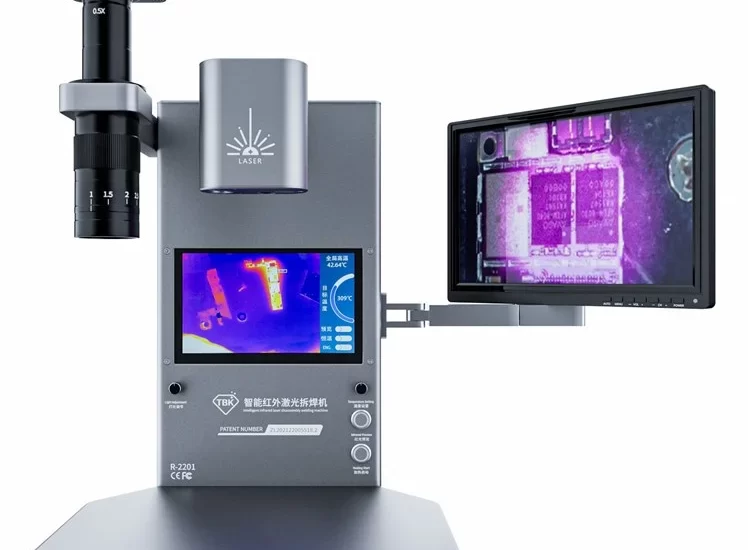

Laser Welding Machine: Precision and Strength in Joining Materials

When it comes to joining materials with precision and strength, a laser welding machine is a top-tier choice. Here’s why laser welding is gaining popularity across industries:

High Precision: A laser welding machine uses concentrated laser beams to fuse materials together. This method provides unmatched precision, making it ideal for applications that require fine details, such as in the aerospace, automotive, and medical device industries.

Strong and Clean Joints: Laser welding produces strong, clean joints with minimal distortion. The focused nature of the laser reduces the heat-affected zone, resulting in less warping and cleaner finishes. This makes it perfect for tasks where the appearance and integrity of the weld are critical.

Versatile Applications: Laser welding machines can handle a wide range of materials, including metals, plastics, and even dissimilar materials. This versatility makes them an invaluable tool in both industrial settings and smaller workshops that require precision welding.

Automation Capabilities: Many laser welding machines can be integrated into automated systems, increasing efficiency and consistency in high-volume production environments. This capability is essential for industries that demand repeatability and precision.

Welding Equipment: The Backbone of Any Workshop

No workshop is complete without a comprehensive set of welding equipment. From traditional arc welders to advanced TIG and MIG machines, having the right equipment is essential for various welding tasks:

Variety of Welding Techniques: Welding equipment comes in many forms, each suited to different materials and applications. For instance, TIG welding is known for its precision and is ideal for thin materials, while MIG welding is favored for its speed and ease of use on thicker materials.

Safety and Efficiency: Modern welding equipment is designed with safety and efficiency in mind. Features such as auto-darkening helmets, fume extractors, and temperature controls ensure that you can work safely and effectively, reducing the risk of accidents and improving the quality of your welds.

Specialized Tools: In addition to the primary welding machines, a well-equipped workshop will also include specialized tools like welding clamps, positioners, and wire feeders. These tools help you achieve more accurate and consistent welds, whether you’re working on a large structural project or a delicate repair.

Adaptability: Welding equipment is adaptable to different environments and tasks. Portable welding units allow you to work on-site or in confined spaces, while larger, stationary machines are suited for heavy-duty industrial applications.

Conclusion

Mastering the use of an air hot gun, a laser welding machine, and other essential welding equipment can significantly enhance the quality and efficiency of your work. Whether you’re looking to add precision to your projects, join materials with unmatched strength, or equip your workshop with the tools needed for a wide range of tasks, these tools are indispensable. By investing in high-quality equipment and understanding their applications, you can ensure that every project you undertake meets the highest standards of accuracy and durability. Whether in industrial manufacturing, automotive repair, or intricate DIY projects, these tools will help you achieve professional results every time.